Automation is a must-have for organizations looking forward to taking the hyper-growth path. Whether it’s about businesses, supply chains, or healthcare, every sector is pulling the levers to leverage the potential of automation and integrate its capabilities into their systems. Wanting to harness the benefits, AI implementation has seen a significant spike, jumping from 35% to 60% within a year, making the retail market the sector with the most rapid increase.

The increase is also a result of industry leaders who are enticed by what automation and AI do and are continuously looking for better automation.

73% of IT leaders credit automation with helping employees save 10–50% of the time they previously spent on manual tasks. Meanwhile, 85% of managers think automating specific tasks will give them and their employees extra time to focus on more critical company goals.

At its core, automation refers to using technology, specifically machines, to perform tasks with little human intervention.

Now imagine this concept applied to the manufacturing industry where millions and trillions of items are being processed. It conjures up images of futuristic factories filled with robots. It’s not all science fiction, though. The reality is that automation is already playing a significant role in the manufacturing industry. The people are using it here, and its influence is growing every day.

Understanding Automated Manufacturing Systems

Before we delve deeper, let’s understand what automated manufacturing systems mean. Unlike the literal robots with metallic arms, automation is a system or multiple systems designed to perform manufacturing processes with minimal human involvement, using various control systems such as computers or robots. They are often used in industries where high volumes of products are produced. They are programmed with specific instructions, ensuring each task is performed accurately and efficiently.

Automated manufacturing systems can be as simple as a single machine performing a specific task or as complex as a full-fledged production line. Think about the assembly line in a car factory. Each robot has a specific job: one installs the wheels, another attaches the doors, and so on, until a shiny new car rolls off the production line.

The beauty of integrating automation in the manufacturing industry is that it can work round the clock, delivering consistent quality while reducing human error.

The Importance of Automation in the Manufacturing Industry

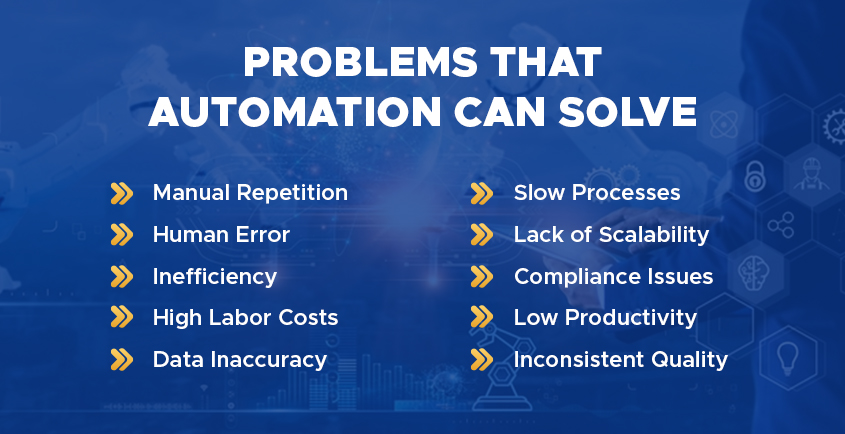

Automation is not just a fancy, high-tech gimmick; it’s a game-changer for the manufacturing industry, becoming a vital tool for manufacturers to stay competitive in today’s technologically advanced world.

One of the main advantages of automation in manufacturing is its efficiency. Automated manufacturing systems can perform tasks much faster than their human counterparts and can do so without taking breaks. This increases productivity, allowing companies to produce more goods in less time.

Moreover, automation reduces the risk of human error, which can lead to costly mistakes. Machines are less likely to make mistakes, and even when they do, they are easier to correct and prevent from happening again. This leads to improved quality, leading to increased customer satisfaction.

Embrace automation with SVAM to address these challenges and optimize your business operations.

Critical Benefits of Manufacturing Process Automation

By now, you’re starting to grasp how to automate manufacturing. But why should you go through all this trouble? Well, the benefits of manufacturing process automation are manifold and far-reaching. A market research company study found that industrial automation can increase productivity by up to 30% in some industries, leading to significant cost savings. The benefits of automation do not end here.

Enhanced Efficiency

Automation optimizes complex workflows by minimizing manual interventions and eliminating repetitive tasks. This streamlines production processes, reduces bottlenecks and ensures tasks are completed precisely. As a result, the entire manufacturing cycle becomes more efficient, allowing resources to be allocated effectively and improving overall operational productivity.

Cost Savings

Automated manufacturing processes lead to significant cost savings. By reducing the need for manual labor and minimizing errors, businesses can cut down on labor costs. Moreover, automation helps efficiently use raw materials, lowering material wastage. Over time, these cost savings accumulate, contributing to improved profitability.

Real-time Insights

Automation provides real-time visibility into various aspects of production, inventory levels, and supply chain operations. With accurate and up-to-date data readily available, decision-makers can make informed choices quickly. This capability enables proactive responses to changing market demands, helps identify and resolve issues promptly, and enhances overall operational agility.

Higher Quality Products

Automated systems follow standardized processes consistently, leading to higher-quality products. With reduced manual intervention, the likelihood of errors or variations in manufacturing decreases. This translates to fewer defects, increased product reliability, and improved customer satisfaction.

Improved Scalability

Automated manufacturing processes are designed to be easily scalable. Computerized systems can handle higher production volumes as demand increases without sacrificing efficiency or quality. This flexibility enables businesses to meet market demands while maintaining operational excellence.

Faster Time-to-Market

Automation accelerates various stages of production, from design to delivery. By streamlining processes, businesses can significantly reduce lead times. This allows products to reach the market faster, enabling companies to capitalize on market trends and gain a competitive advantage.

Embrace Automation in the Manufacturing Industry With SVAM

Remember, automation is not about replacing humans with machines. It’s about using technology to enhance human capabilities to create a safer, more efficient, and more productive workplace.

The journey toward automation may seem daunting initially, but with the proper planning and execution, you can reap its numerous benefits. So why wait? Connect with the subject matter experts at SVAM today to know how we can help with the automation of your business.

We have delivered several automation services for various industries, including law firms, transit, healthcare, and the environment, and seen them grow with automation.

How Can SVAM Help You?

Every business consistently encounters the task of enhancing efficiencies and productivity. Robotic Process Automation (RPA) technology presents a significant opportunity to elevate output, cut costs, and augment productivity by automating manual processes. By implementing RPA, businesses can seamlessly introduce automation and achieve operational efficiencies with minimal risk.

SVAM is at the forefront of guiding clients to recognize the importance of integrating RPA with AI and ML. Through collaboration and incorporating UI Path’s versatile platform, we have designed and crafted comprehensive demonstrations and proofs of concept catering to private and public domains.

Get in touch with us today to learn more about our services and how we can help your business: https://svam.com/contact-us/